BOAT BUILDING OR SCULPTURE?

The Pip Hare Ocean Racing team have been land locked for four months and every time I visit our boat at Carrington’s in the New Forest, I can see big differences. It’s hard not to be on the water, especially when other teams are launching and the British sailing season is well and truly underway, but I just need to take a look at the structures that are being added to our boat day by day to realise this is a job we cannot and must not rush.

We have been planning to upgrade Medallia to big foils since we bought the boat in 2021. Initial conversations with internationally renowned designer Guilluame Verdier, started in February 2022 and a chance meeting with Kevin Escoffier, skipper of IMOCA team Holcim PRB, on the ferry home from France convinced us to partner with him on foil design, and bearings, using the same designs as Kevin’s new boat and with the same contractors to do the work. The program so far has taken hours of planning, pre-work and co-ordination and now we are four months into a six-month refit which will fundamentally change the performance of our 2016 generation boat.

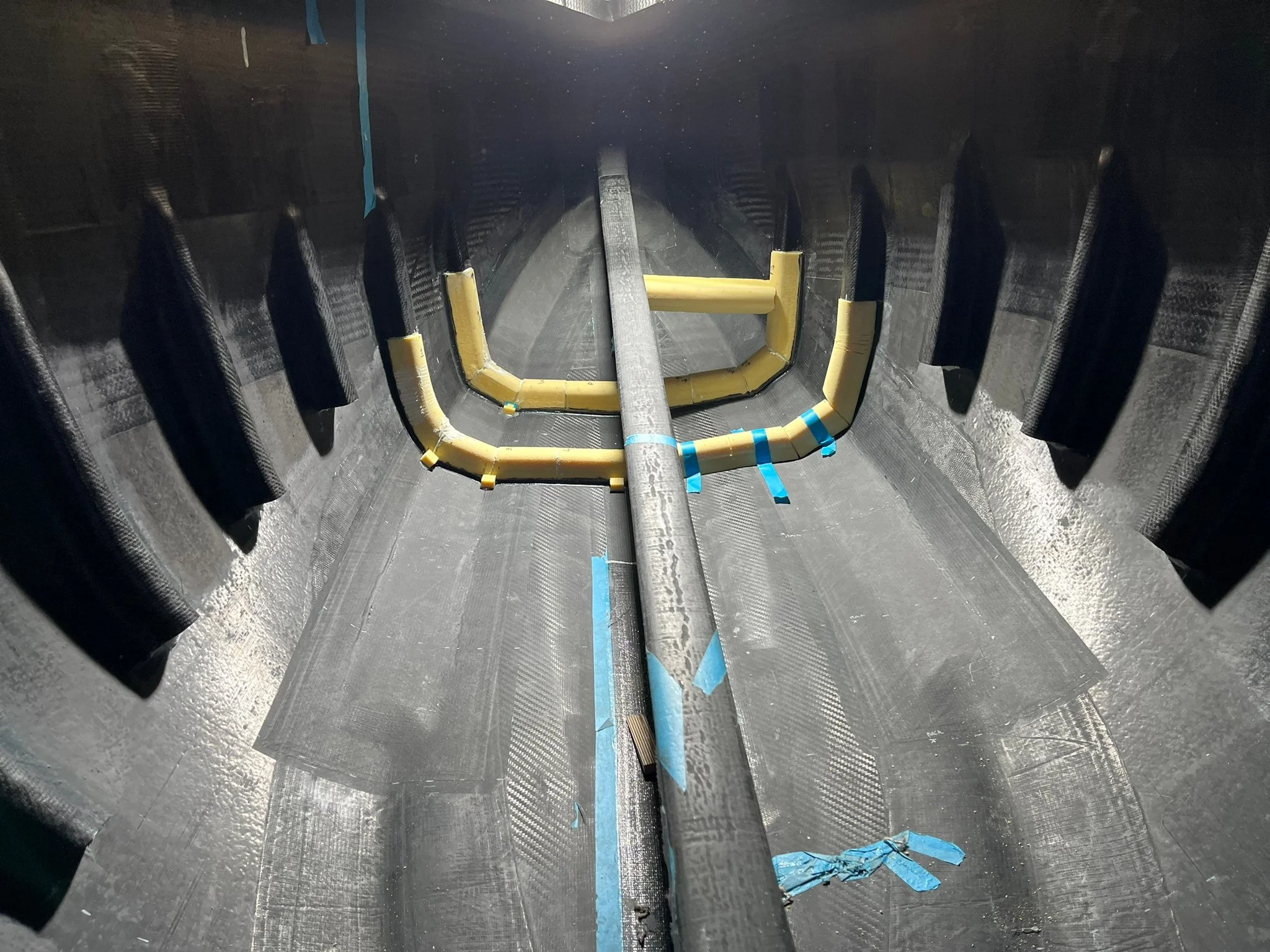

The new foils will be double the size of our last ones, capable of lifting double the weight, projecting the whole hull of Medallia clear of the water. They will be positioned further forward in the boat and naturally will exert different and greater forces on the hull so not only did we need to cover over the existing holes and then cut new ones in the topsides, but we have had to stiffen and strengthen the forward part of Medallia, by adding extra ribs and a full bulkhead (internal wall which bridges across the boat internally to support all deck and hull). All this work is being done by Carrington’s boat builders, who are the premier grand prix boat builders in the UK, with international reputation. The work is specialist, every piece of structure must be properly made, using carbon and epoxy. Individual parts are ‘cooked’ in autoclaves to cure the epoxy, then added to the boat in sequence. The working areas are cramped and the lighting is difficult. This type of work can be dusty, messy and needs to be precise. A rib in the wrong position or badly bonded to the hull, could be dangerous for me at sea, alone. Too much material than required will add weight and affect performance. Having tried my own lamination when things are broken, I can vouch how hard it is to get any sort of decent finish so when I go onto the boat each week and see the beautiful, precise finish of the boat builders at Carrington’s I know I am looking at incredible skill in action. Walking into their yard is not dusty or dirty, the environment it is as clean as a kitchen and every tiny detail matters.

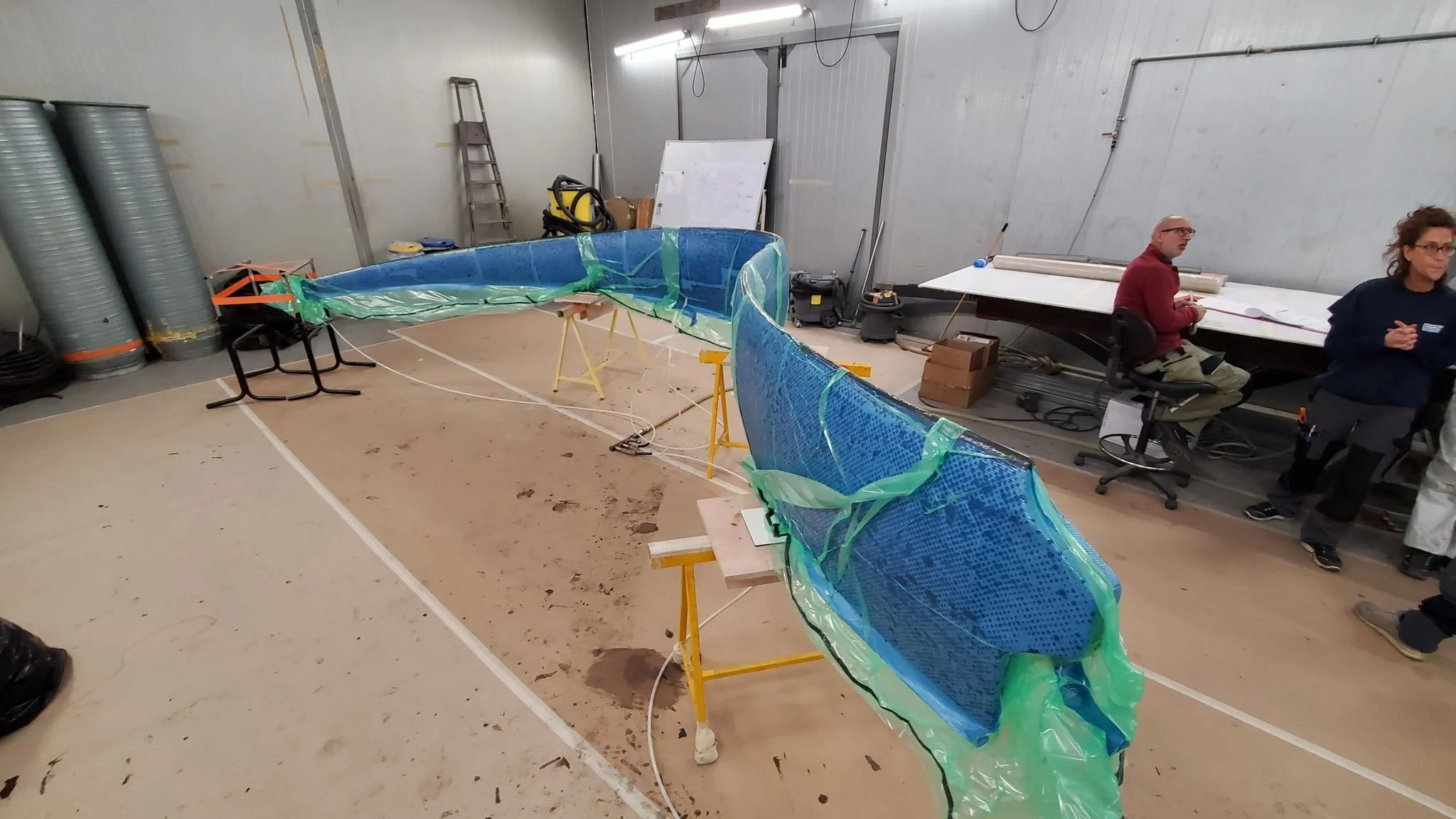

Our foils are being built remotely, at CDK in Brittany. We decided to use this yard because they had already built our sister foils for Kevin Escoffier. It makes total sense to reuse the tooling and go with a team that have already had a ‘trial run’. I went to visit one of the foils mid-production when I was in France this month. It’s huge and beautiful. The foils are built in strips end on rather than top down, the strips are then built up from leading edge to trailing edge, the finished foil can be up to 900 ply of carbon layers at its thickest point. The resultant blocks are milled to the final shape and then wrapped in carbon. They are breath taking, the detail is fine and they look fragile although designed to lift over 7 tonnes of boat.

As well as foils, we are having the foil bearings machined in France. These are the pieces that support the foil snuggly in place, while allowing it to move in and out of the boat and rake forwards to an angle of 5° total. The new exit holes cut into the boat have been 3d scanned, that image has been shared with the bearing manufacturer, who will machine bearings to fit perfectly with no movement against the hull and only allow movement in the desired planes for the foils. He is coming to the UK at the end of April to help put the finished bearings in place.

It's a juggling act, managing all strands of this project and Joff our technical director is working across countries, languages and contractors to make it all happen. Since March he has been joined by our latest recruit, Lazare, a young French naval architect who will be working with us over the next year to support Joff with drawings, ordering parts, making corrections and keeping all plates spinning. It has also made life a lot simpler to have a native French speaker on the team. The refit will all come together at the end of May, when we leave the shed, the foils will be shipped to the UK and we will hold our breath as the whole project made remotely gets slotted together.

I have got used to seeing the boat in bits in the shed now, and sometimes 2022 seems like a remote memory. But we learned a lot and accomplished a lot last year and although we are making huge changes with the foils this winter, there is little we will change around the onboard systems and running rigging as we learned, adapted and upgraded constantly through the last season and we know that part of the boat is sound. Part of this winter refit has involved a simplification and rewiring of onboard electronics, based on our learnings from 2022. I am excited by the prospect of a lot less wires and some much-improved reliability on that front.

Meanwhile I am grounded and I have to admit I am missing sailing a lot. But as ever my work spans across the project and at the moment we are very much focussed on raising awareness of our campaign and I have been on the road quite a bit giving talks. I am sharing stories about my journey since the last Vendée Globe, how we have grown as a team, what it is like to be on the road for a year, the three major races of 2022, how I grew as a competitor and the team flourished to take an overall 8th place in the IMOCA globe series rankings at the end of the year. I could not possibly deliver all the talks I get asked to do and so we have decided to give this talk virtually as well for all those who I cannot get to see face to face, the revenue from ticket sales will go back into the campaign. If you would like to hear from me about the ups and downs of last year, please join us. I will talk for around 70-80 minutes, sharing videos and photos. Giving the back stories and unheard commentary on early season training, The Bermudes Milles, Vendée Arctique and Route du Rhum races. There will be an opportunity for Q&A after the talk curated by my team. The talk will be on the 12th May at 1930 BST. Tickets are £13.55 and can be booked through this link

Following requests from several sources we have also decided to produce a limited edition run of Pip Hare Ocean Racing water bottles for those followers who would like to show their support. The water bottles can be purchased via this link and once again all proceeds will go towards campaign race costs. Helping us keep pushing our performance over the coming year and a half.

We still have 1/3 of our campaign costs to raise before the next Vendée Globe race and this is the thing that takes most of my mental energy at the moment. While we work the boat up through the rest of this year, my time still has to be split between training and fundraising with the aim of raising the remaining sponsorship by the end of the year so I can fully focus on training and performance next year in the six months building up to the Vendée Globe Race start in November 2024. As part of this drive, we plan to auction off our old foils in the hope the proceeds will help us move forwards. The foils are now part of sailing history, they won the Vendée Globe Race in 2016, they still hold the course record and Banque Populaire VIII as our boat was then called, was the first monohull in history to ever circumnavigate with foils. The foils would make great structural ornaments in a garden, or inside a large office lobby. I would love to have kept one myself but I would love to sail really fast around the world on my big foils more. We hope the auction will gain interest and some fans will want to own these pieces of sailing history (we are selling four – the two used in the race and the two originals from when the boat was launched). To find out more about the foils and how to bid please send an email to hello@piphareoceanracing.com

May is not far away so before we know it, we will have a big foil boat and be fully flying. I will continue to share news of our refit, and pictures of the first sail on big foils as it comes round. As ever thank you for your support, your kind words of encouragement and appreciation are always unexpected but hold a huge value to me. November next year is not far away and then we get to go round the world together again.